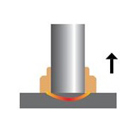

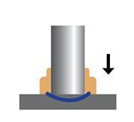

Stud welding allows metal fasteners such as weld studs, weld pins and tapped studs, to be welded onto another metal object using an arc at lightning speed. An arc is produced between the end of the stud and the surface of the workpiece, melting both parts. The stud is then forged into the molten pool. The material solidifies and the stud is welded. The weld is uniform and has complete fusion across the flange. As the whole surface of the weld stud is joined with the workpiece, the resulting weld joint is stronger than the stud or parent material.

Since no holes are punched in the sheet, the workpiece is not weakened and corrosion problems are minimized. When welding the stud, access is only required from one side which means that component handling is considerably facilitated, especially as regards establishing an earth connection.

This absolutely leakproof, hole-free and decorative joining technique is used in many everyday objects and facilitates their handling. Be it coffee machines, cooking pots, flat irons, steam cookers or even in vehicles and roofing – many things would be impossible without stud welding.

Capacitor discharge stud welding has been successfully used for many years all over the world. It allows weld studs with a maximum diameter of M12 to be welded. The welding process is executed by discharging the capacitor battery within a fraction of a second from 1 – 3 ms (0.001 – 0.003 sec.) using the welding element’s ignition tip.

This procedure has proven invaluable especially in vehicle construction, sheet metal forming and decorative metal design.

Drawn arc stud welding is a welding procedure for maximum loads. It enables welding of weld fasteners measuring between 6 mm and 25 mm in diameter. The entire welding process is controlled and monitored by an electronic power source.

This procedure creates high-quality welded connections and has proven invaluable in steel construction, mechanical engineering, shipbuilding, construction of prefabricated parts made from reinforced concrete, door and window construction, structural and civil engineering, fixture and pipeline construction.

Get an Immediate Business Quote